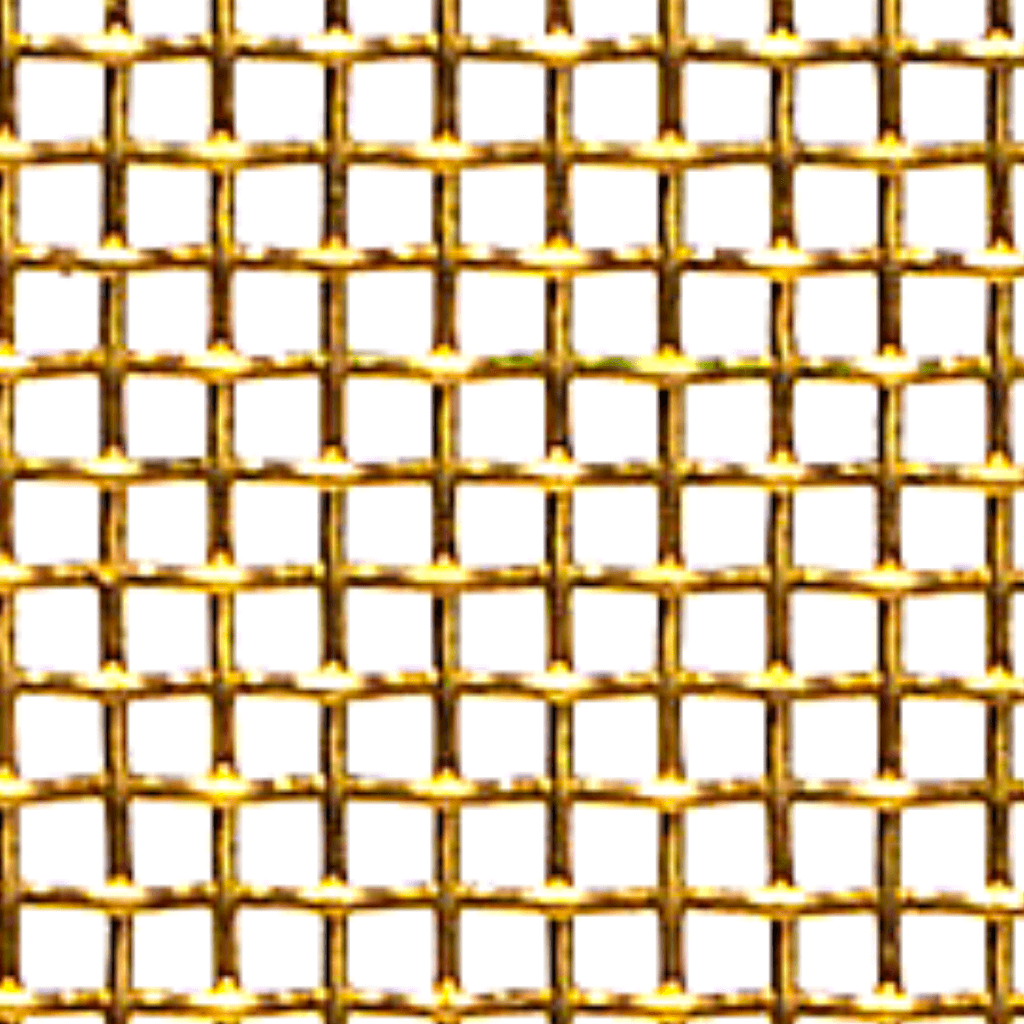

Wire Mesh Brass, Copper & Other Alloy Meshes

Brass

Brass is an alloy that consists of copper and zinc. It is one of the most diverse metals available, making it a useful alloy for a variety of applications. Brass is roughly 28% conductive, which means it thrives in cold environments. While brass is both strong and durable in cold settings, it is important to note that dezincification can occur. Dezincification is the process of removing zinc from an alloy and leaving behind a copper-rich structure with very little mechanical strength. Brass can crack in the event that dezincification occurs.

Copper

Copper has a wide range of applications and is especially useful in the form of wire mesh. Copper’s conductive capabilities make it resistant to corrosion. Great for formability and strength, copper does well in many applications including RFI shielding, HVAC, architectural designs and residential use.

Bronze

Bronze is made up of 90% copper and 10% zinc, making its capabilities very similar to that of copper. The major difference between bronze and copper is that bronze is not conductive. This lack of conductivity makes bronze useful across various applications including marine settings.

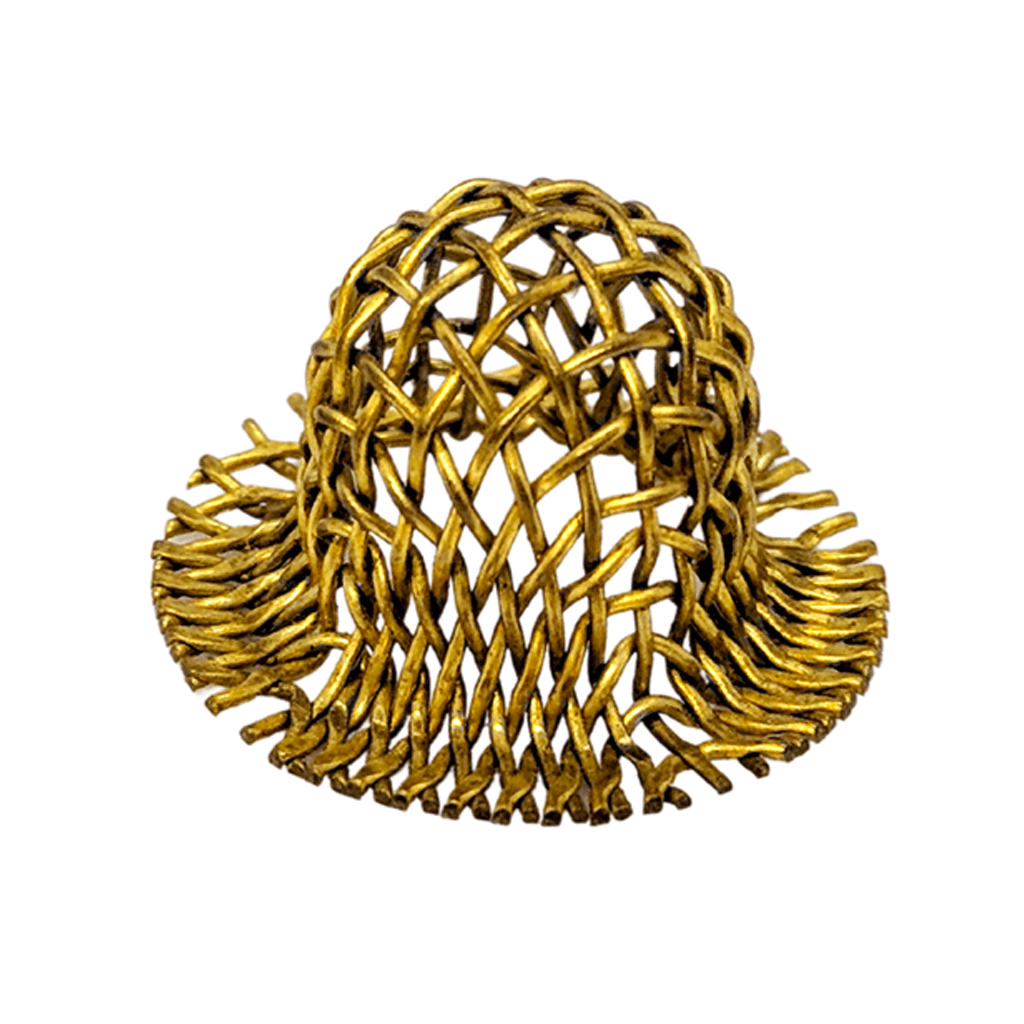

Inconel

Inconel is commonly used in high temperature settings, where corrosion resistance is exceptionally important. This metal consists of nickel-chromium-iron and has benefits including premium strength and durability. Inconel’s long-lasting durability makes it one of the more expensive metals to purchase. Inconel wire mesh is frequently used in heat treating applications to create heat-treated baskets and trays.

Monel

Monel is an offshoot of nickel; its chemical makeup consists of nickel and copper, but also has small traces of iron, magnesium and carbon. This makes Monel both durable as well as resistant to corrosion. It is because of its superior resistance to corrosion that Monel is well known for being one of the best metals for use in seawater. Monel is most commonly used in applications related to ocean settings and involving sea dwelling ships.

Molybdenum

Molybdenum has properties unlike any other metal. It has a melting point ranging between 3200 degrees Fahrenheit to 4750 degrees Fahrenheit. This melting point makes Molybdenum a superior metal for a variety of applications including molten glass and liquid metal forming. This metal offers unique qualities such as high thermal conductivity, giving it a real advantage that other metals do not have.

Hastelloy

Hastelloy is the best metal for withstanding severe corrosion resistance. This metal holds up in the face of a significant amount of corrosion resistance and can also handle hydrochloric acids, giving Hastelloy tendencies like no other metal. The chemical makeup of Hastelloy consists of a nickel-molybdenum-chromium mixed with some tungsten. These two metals combine to make one of the strongest metal alloys available. It is important to note, however, that Hastelloy does not remain strong in high-temperature settings.

Reach out now and get a quote from one of our dedicated sales members.